Why submitting can samples matters

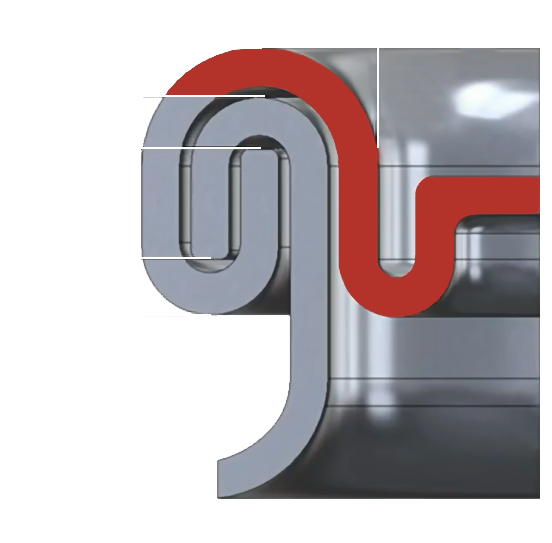

You switch lids unknowingly and suddenly product is leaking and seams are failing. The root cause? An end that’s just 0.002" different. It’s thinner than a sheet of paper but big enough to ruin a batch. These tiny folds of aluminum are your product’s last line of defense, and they’re measured in thousandths of an inch. When your seams are off by even a fraction, it can mean shelf instability, leakage, recalls and reputation damage.

Sending can samples for setting up your seamer is a critical precision step that ensures your seamer is set up to match your exact can and lid specifications. Just because a lid says “202 B64” doesn’t mean they’re all the same - they’re not.

CHECK IT OUT

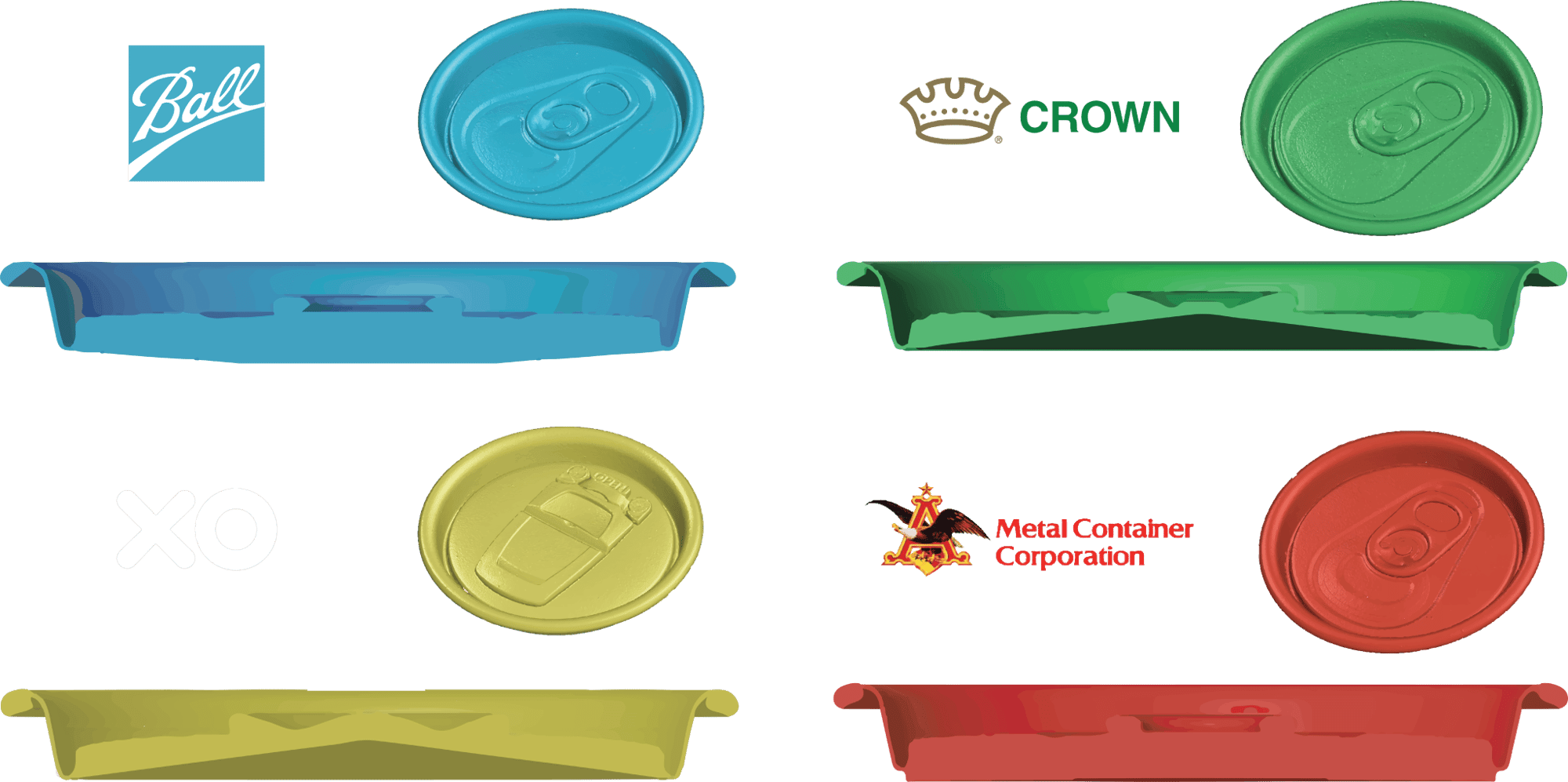

3D scans of widely used B64 lids show variances across manufacturers. Each have proprietary product specifications, and every body/end combo can require unique setup and tooling.

WHY IT MATTERS

Every manufacturer - Ball, Crown & Ardagh included - have minor but meaningful variances in their can and lid dimensions. That variability is a seam failure waiting to happen.

Here's how you can protect your seams

SUBMIT YOUR SPECS

- Submit Specs: Upload technical docs to help us verify fit and compatibility with your seamer.

- Send Can Samples: Send the exact cans and lids you'll be using. This lets us dial in your seamer tooling precisely.

KNOW YOUR SOURCE

- Know Your Source: Buy from a trusted, consistent supplier. If you’re not sure where your ends are coming from, ask.

- Single-Source: Whenever you can, source cans and ends from the same manufacturer.

To ensure your equipment is production-ready and runs smoothly, Cask cannot commit to a confirmed lead time until Can & Lid samples are received. Some formats may require custom parts or seam tooling, which can take additional time to source.