Troubled Monk Customized Their Layout to Double Capacity in Their Existing Facility

Industry

Ready-to-Drink

Challenge

Troubled Monk was running their previous canning system 16 hours per day, 7 days a week in order to keep up with skyrocketing demand for their new Hard Iced Tea line. They needed to double their production capacity and add Nitro-Dosing capability, but were very extremely limited on space.

Results

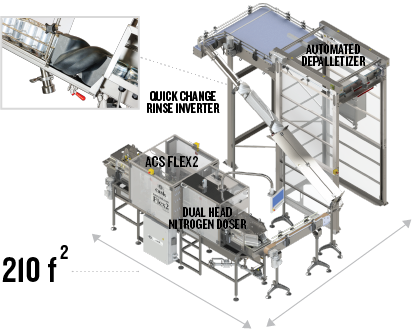

Cask worked with Troubled Monk to customize a layout for a turnkey 100 can per minute ACS FleX2 set-up, enabling them to scale in their existing facility and reduce packaging time by 2.5x.

System

ACS FleX2

We saw the turnkey ACS FleX2 set-up with an Automated Depalletizer at a trade conference and couldn't believe how compact it was. Working on a custom layout to double our capacity quickly in our existing space was instrumental to our next phase of growth.

Charlie Bredo

Co-Founder @ Troubled Monk Brewery

The Challenge

Troubled Monk experienced exponential growth with the launch of their Hard Iced Tea line. To meet demand they were packaging 16+ hours per day to keep up with demand. With limited production space available they felt bound to their existing equipment capacity for the foreseeable future, limiting growth potential and waring their staff thin.

The Solution

Cask worked with Troubled Monk to customize a turnkey layout that would fit into their confined production space. The set-up includes an Automated Depalletizer, ACS FleX2 and an integrated Nitrogen Doser. Each component of the equipment is designed to save time, cost and space.

Nitrogen Dosing: The Dual Head Chart CryoDoser is a fully integrated Nitrogen Dosing solution developed by Cask to eliminate added footprint and need for purchasing separate UltraDosers, reducing costs by 20%. The PLC-integrated controls enable progressive nitrogen dosing, ensuring the same volume of LN2 from the first can to the last so there is no variation in quality or firmness across batches.

Pre-Rinse: The Quick Change Rinse Inverter cuts can size changeover time down to minutes. Add-on features for UV-C and Ionized Air Treatment also eliminate water usage in the pre-rinse process to conserve utility costs and waste.

The Results

Troubled Monk more than doubled their capacity, drastically reduced labor time and added new capabilities for product lines with their integrated Nitrogen Doser. This has allowed them to capitalized on market share in their burgeoning beverage category.