Getting started with used equipment

Owning a Cask system, whether brand new or brand new to you, is a big step. We're here to make sure it's a successful one. Use this 5 step guide to get set-up for success with your used equipment.

STEP #1

ACCOUNT SET-UP

Complete your account set-up. This provides us with key information to support you quickly when you need a hand.

STEP #2

SCHEDULE A 30MIN TECH CONSULT

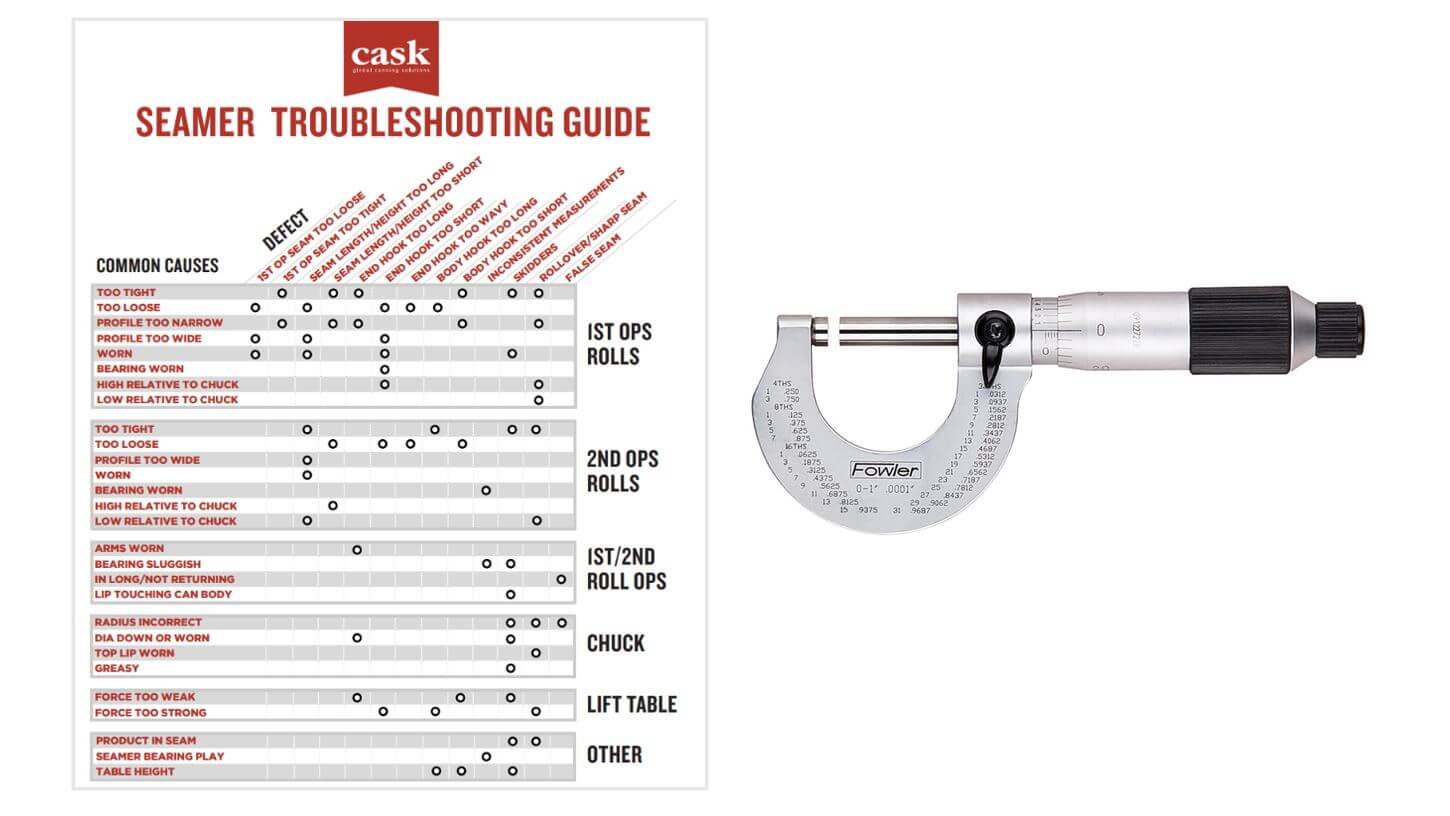

Ensuring you have the proper seamer set-up for your specific can & lid specs is critical. Specs vary greatly even across the same lid styles, and improper set-up can mean a seaming disaster (learn more here). Used equipment always has its own maintenance and set-up history - The Cask Team will do a virtual system walk-through with you to get you tooled for success.

*Variations of common B64 lids across manufacturers

STEP #3

BOOK TRAINING & SERVICE

Training provides the critical foundation that makes the learning curve of packaging far less steep, and gives teams the tools they need to truly be successful out of the gate.

Check out a customer story from Smooth 42 Craft Distillery, and why they see on-site training and service as the most critical part of their used system purchase.

STEP #4

ADD-ON BUNDLES

Pair your used system with add-ons like an Automated Depalletizer or Date Coder and we'll bundle your purchase. Cask Technicians can commission add-ons when you book your on-site training and service.

STEP #5

SYSTEM MAINTENANCE

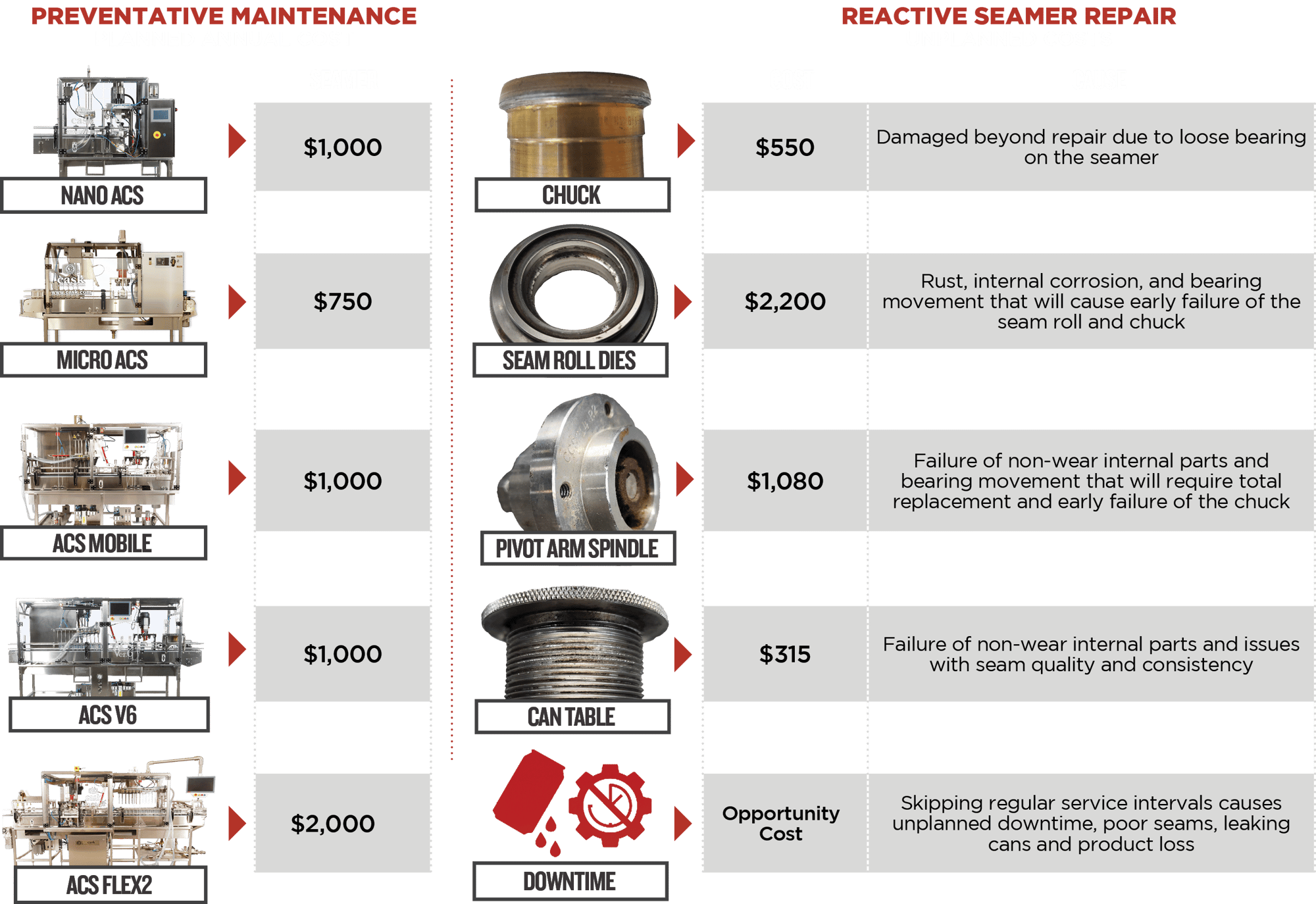

You never know how your used equipment was previously maintained. Starting fresh with proper fill head and seamer maintenance protects your investment. System maintenance helps ensure product quality, and avoid unplanned downtime and costly full replacement of wear parts.

*Seamer failure use case

Cask "how-to" tools and resources

Use these quick guides for troubleshooting common issues and tips and tricks from Cask Technicians for operating your canning system more efficiently.